About linen textiles from Klässbols

Denmark has 'Georg Jensen' - Sweden has 'Klässbols'

Klässbols is a Swedish family business that goes back to the end of the 19th century.

The textiles represent the best in the art of weaving and premium quality.

Since the 1970s Klässbols Linneväveri has had the honour of supplying the Swedish royal house with exclusive tablecloths in the form of hand-woven tablecloths and napkins, furniture, embroidery and curtains.

In addition, Klässbols Linneväveri has for 30 years delivered specially designed tablecloths and napkins for the annual Nobel Prize ceremony.

The family collaborates with nationally and internationally renowned designers and has received several design awards.

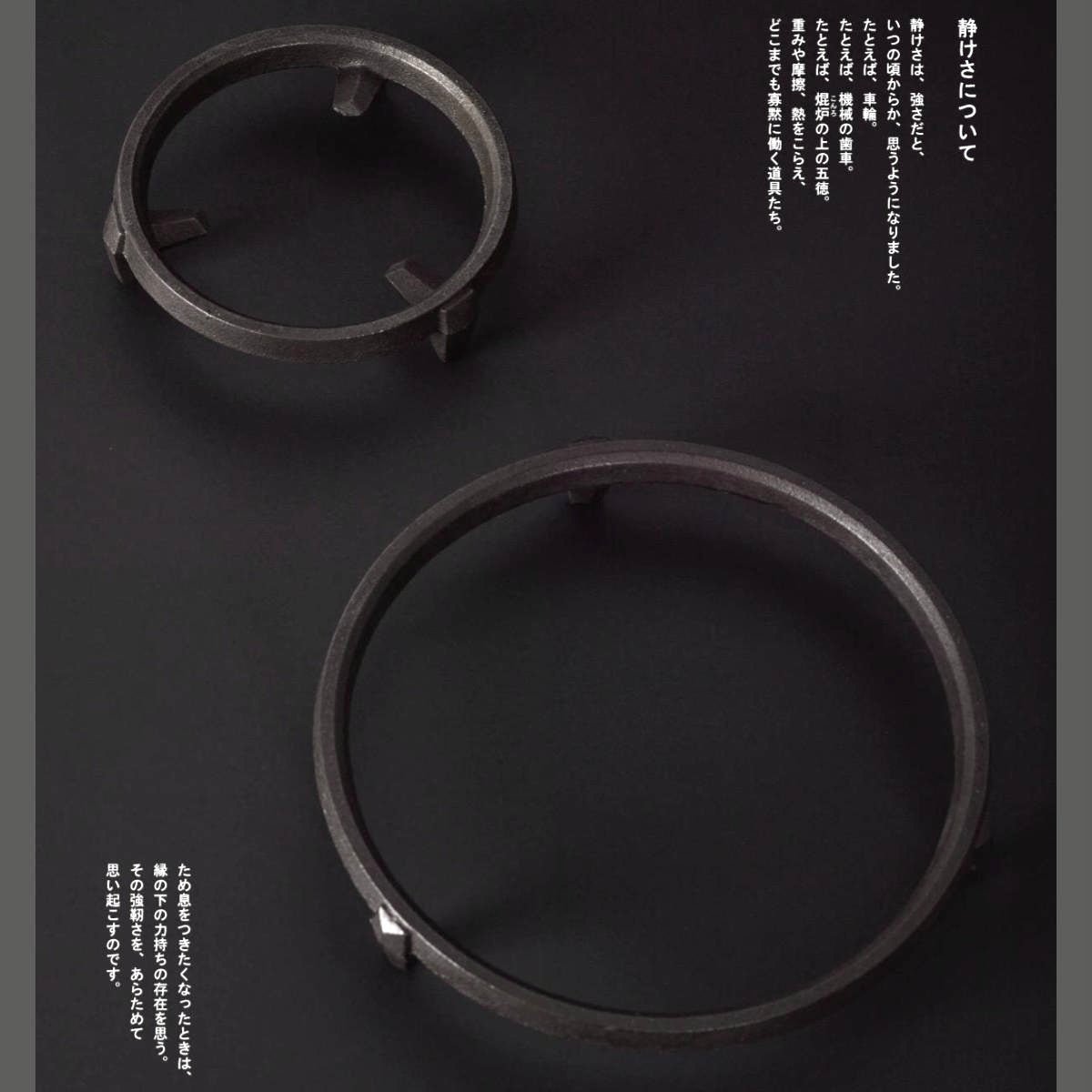

Many manufacturers choose to weave their textiles in very broad and long lanes, which are subsequently cut and folded, after which the edges are sewn with an ordinary stitch.

Klässbols weave their products to the edge, i.e. That all products are individually woven and therefore have a very beautiful and complete look.

All products are designed and woven in Sweden, so you will not find more exclusive and beautiful linen textiles.

The history of flax

As early as the Stone Age, flax could be processed in Europe, though it was mostly used for things like ropes, fishing nets and the like.

Clothes were not so developed at the time. Hardly anyone thought about the tablecloth, not to mention the napkin. In ancient Egypt, people began to dress in beautiful, cool linen. Flax was the only material allowed in priestly clothing, and the mummies were wrapped in fine linen, many of which are still preserved today.

From Egypt, knowledge spread over Babylon, which in ancient times was the centre of the "flax industry", through Greece to the Roman Empire and further up into Europe. In the Roman Empire, in ancient times, there were large flax workshops in Ravenna and Vienne, which were under strict control of the 'procuratores linificiorum', which says something about the meaning attributed to the material. In the Nordic countries, we have been able to process flax since at least the Bronze Age.

Around the year 1530, the spinning wheel was invented, further accelerating the production of flax. Flaxworking was a craft for a long time. When the machines arrived in the late 1700s, the biggest competitor to flax arrived with them – cotton. Better machines came, which were also suitable for the flax industry. In 1805 Joseph Marie Jacquard constructed his epoch making machine for pattern weaving, which among other things opened new opportunities for Damascus weaving.

The flax has had fierce competition from simpler and cheaper materials, and more than once it has been thought that it would disappear completely. The quality and aesthetic value of the flax have proven to survive all "newcomer materials", including the synthetic fibers of recent years.

Fortunately, it now seems that flax is entering a new age of glory - in a world on the way back to sustainability and quality consciousness.

About flax

The long fiber of flax is suitable for weaving, and its use can be traced back nine thousand years. In the 18th century there were several famous Nordic Damascus gardens and the blue-flowered flax fields were breathtakingly beautiful. Eventually, cotton took over as the most common textile fiber, and the difficult-to-process linen ended up in the shade. Today, flax is only in the Nordic countries to a limited extent. But flax has had a renaissance. The awareness of nature has gained a strong foothold, and more and more people appreciate the tradition and the uniqueness of the characteristics of flax.

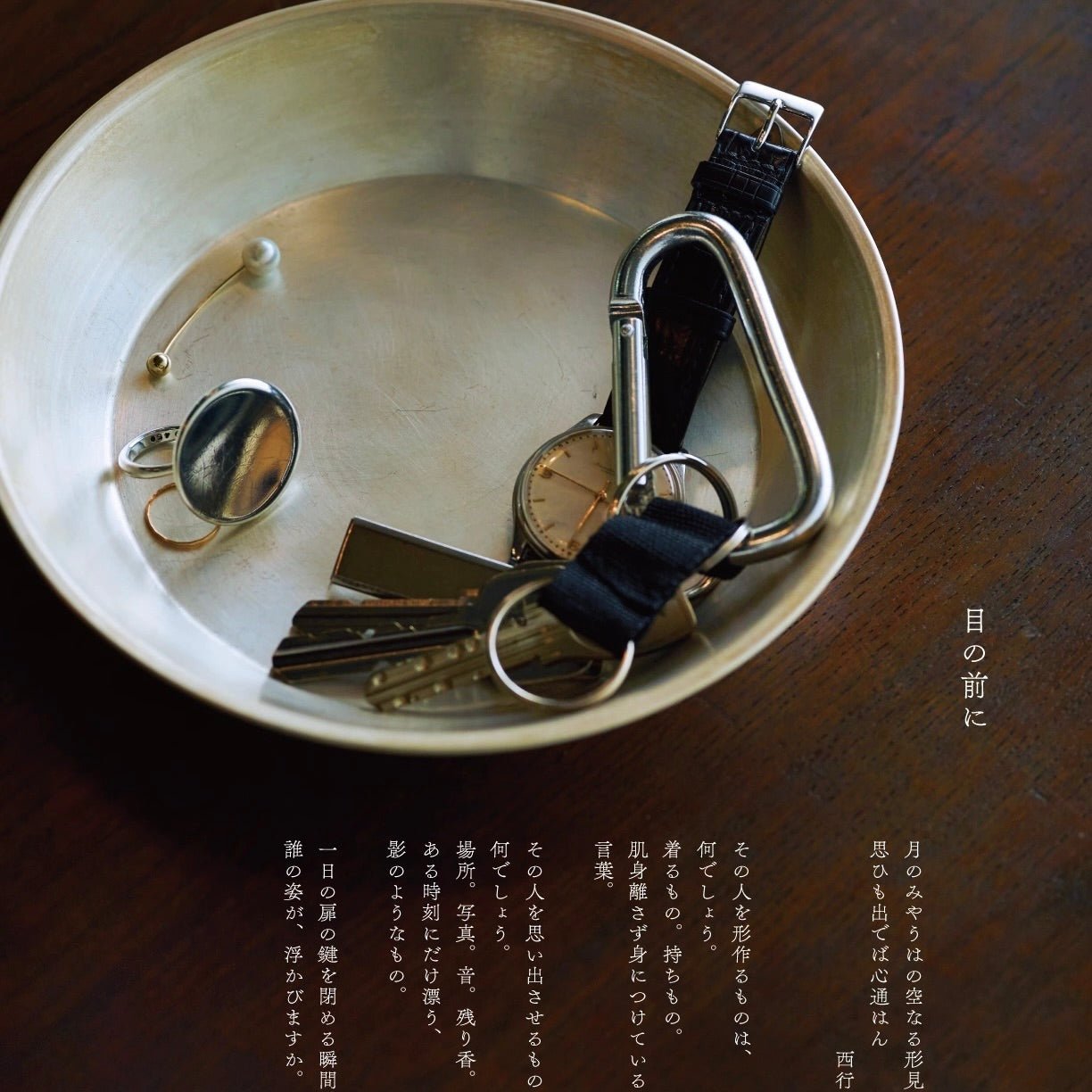

The flax fiber has extreme strength and suction. The substance is fast drying and smudge repellent. If you spill liquid on the substance, it is absorbed immediately. Linen wipes are excellent in the kitchen to dry glass and to give silver and crystal a beautiful shine. Flax also feels cool to the skin.

Washing and care

Flax textiles should be washed at 60°C, but difficult spots may require a higher temperature, however not higher than 80°C. Flax is a durable material, and best of all, a good choice for the environment. Always expect shrinkage of about 5-7% when you wash the linen fabric for the first time.

A fine linen fabric that has been properly treated has a beautiful shine and a cool and smooth surface.

1. Softening

Place the new linen in lukewarm water for at least 20-30 minutes before washing to avoid folds, but also to contribute to more water in the washing machine.

2. Detergent

We recommend detergents for coloured washing for all our textiles, or detergents without bleach.

3. Water-rich programme

All new flax material releases excess fiber at the beginning, which must be flushed out in the wash. Set the washing machine to the program with the most generous amount of water. Do not wash with the eco program, as it uses little water.

Wash at 60°C and wash flax separately and not with other materials, as excess flax fibers can get stuck on the clothing.

If you have a difficult stain that requires a higher temperature, you can increase the temperature, but never above 80°C, as the linen can then fall in elasticity, shine and strength.

4. Drying - centrifugation and drying

For centrifuging, only low speed (400-800) should be used. Remove the centrifugation completely if possible. At high speeds, fibres can be broken, resulting in deterioration of quality and more excess fibres. When the sink is finished, clean the door on the washing machine for lint.

Hang to dry after washing. Natural and coloured linen should not be dried in bright sunlight.

We advise against using a dryer. However, the 'BADA' towels can withstand drying at low temperature if desired.

5. Irrigation

Stretch the damp linen after washing and hang to dry. If you want to iron your fabric, do so while the fabric is moist and with a warm iron (three dots).

Featured collections